The Ford 9-inch rear end, so named because of its 9-inch ring gear diameter, was manufactured from 1957 to 1987 by the Ford Motor Company and installed in some intermediate and most full-size Ford, Lincoln, and Mercury passenger cars, F-Series ½-ton trucks, and Econoline vans. Its overall strength and availability are its greatest attributes, and 9-inch units are available with either 28- or 31-spline large diameter axles.

The 9-inch rear end housings, also noted for their sturdiness, were built with case thicknesses ranging from .150″ to .250.” Through the years, the 9-inch was offered in seven different housing widths, from 57-1/4″ to 69-1/4″, any of which may be suitable for a particular race or street vehicle. Many street stock circle track and drag racers prefer the 9-inch rear found in ’66-’70 full size Fords and Mercurys, ’71-’72 Lincolns, and ’68-’72 F100 Ford trucks because it has 31-spline axles, large ball-type axle bearings and a 61″ overall width (measured from drum face to drum face).

Some of these units also have large 3-1/4″ axle tubes, rather than the standard 3″ tubes. Remember though, that a traditional 9-inch third member must be exchanged for the unacceptable 9-3/8” ring gear found in most housings with the 3-1/4 tubes. Another favorite, especially with street rodders, is the ’79-’81 Lincoln Versailles rear end. An extra-thick wall housing, factory disc brakes, 28 spline axles, large ball-type axle bearings, leaf spring mounting pads and a 58-1/2″ overall width make it a natural swap in most cars of the thirties and early forties.

The removable center section of the 9-inch rear end allows the ring and pinion gears to be set up on a bench, rather than in the housing, and rear end ratios can be changed quickly. Racers can also carry extra center sections with different ratios for experimentation purposes. Strengthwise, the most desirable center sections are those made from nodular iron, easily identified by a large “N” on the outside of the casting.

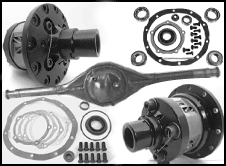

The aftermarket produces a wealth of heavy-duty 9-inch rear end parts engineered for street and racing applications. Complete housings, carriers, spools, mini-spools, axles, housing ends, bearing and shim kits, pinion supports, and yokes are all available from Ford Racing, Mark Williams, Strange Engineering, and Allstar Performance. Spools and yokes are available in steel as well as lightweight aluminum, and super light but costly titanium. Ring and pinion manufacturers like Richmond offer a multitude of gear ratios.

There are several helpful hints to promote longevity of the Ford 9-inch rear end according to the experts at Mark Williams. Most replacement 9″ ring gears require modifications to prevent interference in the area of the case where the pinion pilot bearing is located. Rather than machining the housing, the ring gear should be carefully chamfered using a small die grinder to provide adequate clearance in this area.

Rears used in oval track applications should have either a custom baffle or internal housing seal (Allstar Performance #ALL72100 – #ALL72104) installed to prevent gear oil from building up inside the right axle tube. Enthusiasts should take great care in selecting the correct bearing/shim kit when performing a gear change or overhaul as the 9-inch rear has been fitted with a variety of different carrier and pinion bearings over the years.

Prior to ordering, it is vital to know the size of the carrier bearings (2.891”, 3.062”, or 3.250”), pinion spline count (28- or 35-spline), and whether a standard, Daytona-style, or heavy-duty aftermarket (Strange or Mark Williams) pinion support is used.

An upgraded pinion support is another worthy addition to any 9-inch rear end. The heavy-duty, “Daytona” style support (Allstar #ALL68396 or Strange Engineering #STGN1914) available for use with standard 28-spline pinions accepts a larger rear pinion bearing for increased durability and is particularly popular with oval track racers.

Because drag racing applications place a tremendous amount of stress upon the rear axle assembly, a heavy-duty drag race pinion support (Strange Engineering STGN1915) is often preferred. It features both larger front and rear pinion bearings, and also allows compatibility with 28- or 35-spline pinions.

Finally, regardless of application, all 9-inch rears should be fitted with a bung and cap for easy filling. The specialists at Mark Williams recommend filling with four quarts of Torco 85W140 racing gear oil (Torco # TRCA248514CE) for best lubrication.