It’s easy for a novice to think of an engine upgrade solely in terms of adding a set of domed high-compression pistons when, instead, his initial thoughts should focus on strengthening the bottom end. For simplicity’s sake, we’ll confine our definition of “bottom end” to the crankshaft and the main bearing and connecting rod bearing areas of the block.

Replacing the stock main and rod bolts with high-performance hardware should be the first step in the upgrade. A production cylinder block fitted with stock main and rod bolts may work fine in a street performance application, but when the horsepower output of the engine progresses well beyond stock, a bolt-related failure becomes much more likely when using the stock bolts. This is especially true if nitrous oxide or forced induction like a supercharger or turbocharger has been added to the mix. Any of these modifications can send cylinder pressures through the roof and place much more strain on the bottom end components.

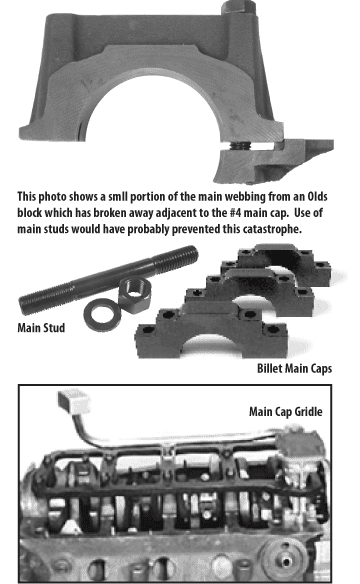

With regard to building strong bottom ends, keep in mind that many engine blocks produced after the mid-seventies were subjected to drastic weight reduction measures as manufacturers strived to achieve lighter, more fuel-efficient cars. These efforts often went as far as opening “windows” in the main webbing areas of the blocks, which lightened the block somewhat but compromised the structural integrity in the process. Lightened blocks should never be considered for serious performance applications because the bottom ends cannot withstand any extra pressure.

According to fastener experts, connecting rod bolts are the most important fasteners in an engine, and also the most highly stressed, due to the tremendous alternating tension and constant cycling they must endure during each rotation of the crankshaft. The big end of the rod is repeatedly distorted to an oval shape, actually flexing the rod bolts, and then returns to a round shape as the crank continues through each cycle.

New rod bolts should be installed by a machinist at the same time the connecting rods are resized. Several grades of high-performance rod bolts are available. Choose the ones that will be sure to stand up to the degree of modifications anticipated. Remember that during rod cap installation, rod bolts stretch as they are torqued. The amount of stretch can be determined with a specialized tool called a stretch gauge which can accurately measure the exact amount a bolt stretches as it’s tightened. Bolts must be rechecked during subsequent rebuilds to determine if they have been stretched beyond safe limits and must be replaced.

Stock main cap bolts are not acceptable for race applications either. High cylinder pressures will often overcome the strength of the caps and stretch the bolts, causing the main caps to “walk” and actually bounce on the block’s mating surfaces, eventually damaging the contact area. This can, in turn, loosen the main bearings in their saddles to the point where the engine loses oil pressure or the bearings spin.

A basic main cap upgrade would consist of replacing stock main bolts with high-performance bolts. A step up from this would be the installation of main studs instead of bolts. From here, aftermarket main caps would be the next logical upgrade to increase the strength of the bottom end. To achieve maximum bottom end strength, a main cap girdle would be the ultimate bottom end strengthening device.

Advantages of main studs include easier assembly and disassembly, improved block life through reduction of the stress placed on the threads, and more accurate torque readings because studs don’t twist in the block. Main stud installation involves first running the appropriate tap through each hole to clean the threads, washing the studs, and then screwing them into the block until they are finger tight. Prior to final installation, the studs should be examined to see that thread length is sufficient and that there is no chance that the nuts can “bottom out”. If the studs are to be permanently installed, they may be lightly coated with Loctite. After the main caps have been installed and checked for fit, the threads, nuts, and washers should be thoroughly lubricated prior to being torqued to specifications using a torque wrench that is known to be accurate or has been recently calibrated by a reputable machine shop. When lubricating washers, only the top side should receive lubrication to prevent incorrect torque readings.

Billet main caps are offered by several aftermarket companies and are recommended for applications subjected to extreme RPM, supercharging, or massive amounts of nitrous oxide. Billet caps are much stronger than cast caps and are even available in conversion packages for engines that didn’t originally have four-bolt mains from the factory. Cap installation can be a bit costly because the caps must be fitted prior to align boring the block.

A main cap girdle, made from a single piece of precision machined billet steel or aluminum, is used with production main caps and studs to strengthen them and, at the same time, tie the entire lower block together for greater durability. These girdles are available for several popular engines.

Building a bulletproof bottom end is not an inexpensive undertaking, but in terms of overall engine longevity and costs, spending money wisely in this area can avoid a much bigger expense down the road.