Often taken for granted, brake fluid is a critical ingredient in the preparation of any high-performance vehicle, particularly if it’s expected to endure the rigors of circle track racing. Racers may install specialized braking systems designed to handle the stresses associated with competition but may not scrutinize their choice of brake fluid properly, yet may wonder why their costly new brake system didn’t perform as expected.

First and foremost, only glycol-based racing brake fluids should be used due to their higher temperature rating. Brakes get extremely hot under racing conditions, causing anything but the best fluid to boil and, in turn, lead to a “spongy” pedal, or even a complete loss of braking!

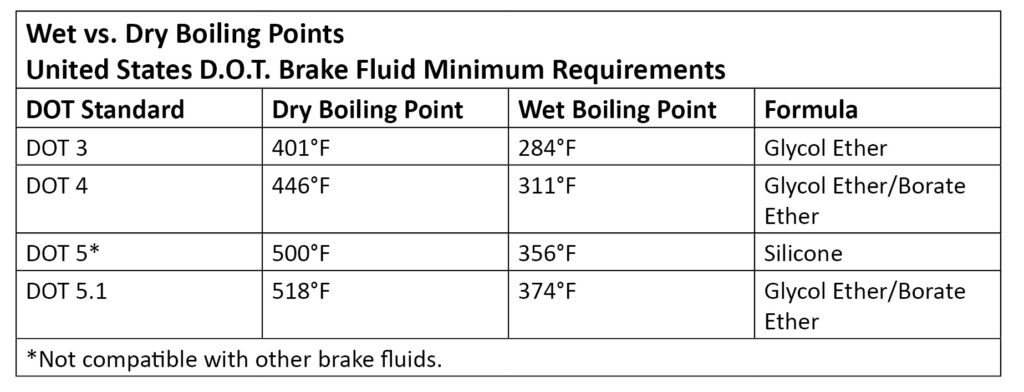

When selecting the appropriate fluid, take into consideration both the wet and dry boiling points specified by the United States Department of Transportation (DOT), listed in the chart below. When subjected to the high braking demands common to racing, a fluid that exceeds DOT 3 or DOT 4 standards is highly recommended.

The dry boiling point of brake fluid is measured when the fluid is completely free of any moisture contamination. The wet boiling point refers to fluid that has absorbed moisture, which can significantly reduce the minimum boiling point of the fluid. The DOT 4 requirement for dry boiling point is 446°F, for example, while the wet boiling point is 311°F.

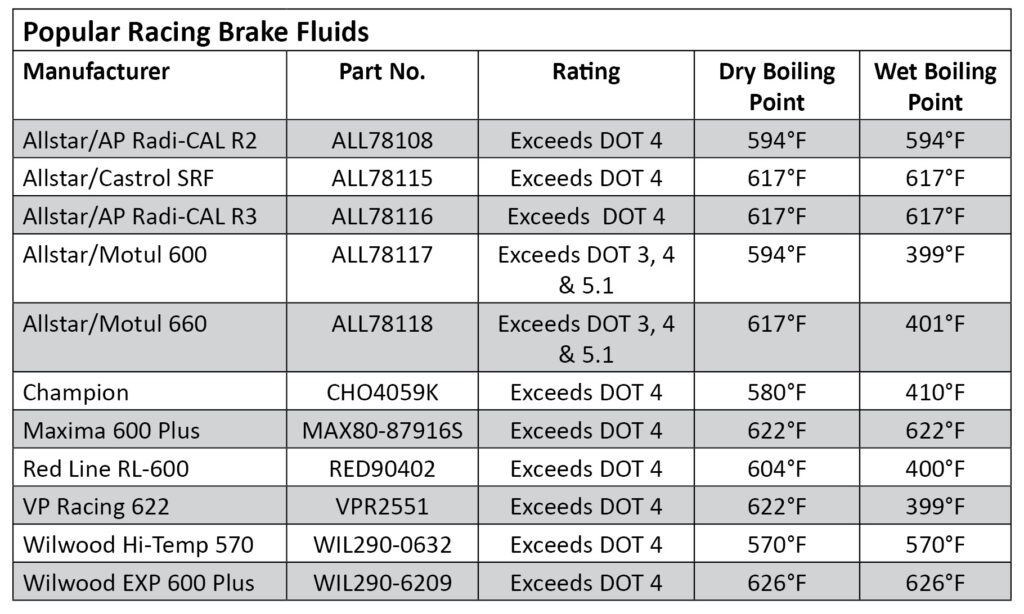

There are many brands of brake fluid currently offered that exceed DOT 3 or 4 specifications, including those from Allstar Performance, Motul and Wilwood. Wilwood’s EXP 600 Plus, for example, features a dry boiling point of 626° F, well above the DOT 4 requirement of 446° F. In addition, Wilwood’s fluid utilizes a low-viscosity formula which eases the process of brake bleeding, and also reduces foaming under the heavy “pedal pumping” conditions that are common to circle track racing.

While silicone-based fluids are DOT 5 rated, they have both distinct advantages and disadvantages. DOT 5 fluid has a very high boiling point, and it will not absorb moisture from the atmosphere like glycol-based fluid. However, silicone brake fluid should never be used in a race car because its higher viscosity can cause the calipers to “drag”. Silicone fluids expand in high temperature situations, creating more compressibility and causing a very “spongy” brake pedal. Some manufacturers have also found in testing that silicone fluids contain properties which can cause the seals to swell. It is additionally not compatible with other brake fluids and should never be mixed with DOT 3 or DOT 4 brake fluids. DOT 5 brake fluid is, however, popularly used in classic cars that often remain in storage for long periods and require a fluid that doesn’t absorb water.

DOT 5 fluid should NOT be confused with DOT 5.1, which is intended for use in high-performance and heavy-duty applications, and is compatible with DOT 3 and DOT 4 brake fluids. While not a racing fluid, Motul’s DOT 5.1 fluid (MTL100951), is 100% synthetic polyglycol-based and is engineered specifically for use with anti-locking brake systems.

Because glycol-based brake fluids absorb moisture quickly, it is imperative that the fluid in the system always be kept fresh to avoid problems. Also, the master cylinder reservoir cover should be kept in place at all times, except when servicing. Fluid containers should be kept tightly sealed when not in use and never re-use any fluid after it has been bled from the system.

It’s a good idea to periodically flush the system just to keep the brake fluid optimally fresh. Anytime you experience severe brake fluid temperatures, flush the system as soon as possible. It is equally important that fluid shouldn’t be stored in pressure bleeders as the contained fluid is exposed to air and moisture, allowing it to quickly deteriorate. A brake bleeding kit, such as the Power Bleeder Pro from Motive Products (MTP0250) would be helpful at this point. It includes a pressure bleeder, two bleeder bottles, hoses, a variety of master cylinder adapters, and complete instructions.

If you are suspicious of a problem possibly related to high brake fluid temperatures, you can purchase brake temperature probes for use with pyrometers from Intercomp (INT360022) and Longacre (LON52-50740). These probes are designed to measure the surface temperature of components such as calipers, rotors, and other brake system elements to indicate potential issues.

By choosing a quality brake fluid, and keeping the fluid fresh and free of moisture, you are much less likely to run into problems like boiling brake fluid. After all, if your brake fluid boils – causing your brakes to fail – and you take a nice turn into the wall, your blood may also begin to boil (as you contemplate some much costlier expenses).

Often taken for granted, brake fluid is a critical ingredient in the preparation of any high-performance vehicle, particularly if it’s expected to endure the rigors of circle track racing. Racers may install specialized braking systems designed to handle the stresses associated with competition but may not scrutinize their choice of brake fluid properly, yet may wonder why their costly new brake system didn’t perform as expected.

First and foremost, only glycol-based racing brake fluids should be used due to their higher temperature rating. Brakes get extremely hot under racing conditions, causing anything but the best fluid to boil and, in turn, lead to a “spongy” pedal, or even a complete loss of braking!

When selecting the appropriate fluid, take into consideration both the wet and dry boiling points specified by the United States Department of Transportation (DOT), listed in the chart below. When subjected to the high braking demands common to racing, a fluid that exceeds DOT 3 or DOT 4 standards is highly recommended.

The dry boiling point of brake fluid is measured when the fluid is completely free of any moisture contamination. The wet boiling point refers to fluid that has absorbed moisture, which can significantly reduce the minimum boiling point of the fluid. The DOT 4 requirement for dry boiling point is 446°F, for example, while the wet boiling point is 311°F.

There are many brands of brake fluid currently offered that exceed DOT 3 or 4 specifications, including those from Allstar Performance, Motul and Wilwood. Wilwood’s EXP 600 Plus, for example, features a dry boiling point of 626° F, well above the DOT 4 requirement of 446° F. In addition, Wilwood’s fluid utilizes a low-viscosity formula which eases the process of brake bleeding, and also reduces foaming under the heavy “pedal pumping” conditions that are common to circle track racing.

While silicone-based fluids are DOT 5 rated, they have both distinct advantages and disadvantages. DOT 5 fluid has a very high boiling point, and it will not absorb moisture from the atmosphere like glycol-based fluid. However, silicone brake fluid should never be used in a race car because its higher viscosity can cause the calipers to “drag”. Silicone fluids expand in high temperature situations, creating more compressibility and causing a very “spongy” brake pedal. Some manufacturers have also found in testing that silicone fluids contain properties which can cause the seals to swell. It is additionally not compatible with other brake fluids and should never be mixed with DOT 3 or DOT 4 brake fluids. DOT 5 brake fluid is, however, popularly used in classic cars that often remain in storage for long periods and require a fluid that doesn’t absorb water.

DOT 5 fluid should NOT be confused with DOT 5.1, which is intended for use in high-performance and heavy-duty applications, and is compatible with DOT 3 and DOT 4 brake fluids. While not a racing fluid, Motul’s DOT 5.1 fluid (MTL100951), is 100% synthetic polyglycol-based and is engineered specifically for use with anti-locking brake systems.

Because glycol-based brake fluids absorb moisture quickly, it is imperative that the fluid in the system always be kept fresh to avoid problems. Also, the master cylinder reservoir cover should be kept in place at all times, except when servicing. Fluid containers should be kept tightly sealed when not in use and never re-use any fluid after it has been bled from the system.

It’s a good idea to periodically flush the system just to keep the brake fluid optimally fresh. Anytime you experience severe brake fluid temperatures, flush the system as soon as possible. It is equally important that fluid shouldn’t be stored in pressure bleeders as the contained fluid is exposed to air and moisture, allowing it to quickly deteriorate. A brake bleeding kit, such as the Power Bleeder Pro from Motive Products (MTP0250) would be helpful at this point. It includes a pressure bleeder, two bleeder bottles, hoses, a variety of master cylinder adapters, and complete instructions.

If you are suspicious of a problem possibly related to high brake fluid temperatures, you can purchase brake temperature probes for use with pyrometers from Intercomp (INT360022) and Longacre (LON52-50740). These probes are designed to measure the surface temperature of components such as calipers, rotors, and other brake system elements to indicate potential issues.

By choosing a quality brake fluid, and keeping the fluid fresh and free of moisture, you are much less likely to run into problems like boiling brake fluid. After all, if your brake fluid boils – causing your brakes to fail – and you take a nice turn into the wall, your blood may also begin to boil (as you contemplate some much costlier expenses).